How Prosthetics Are Made: A Conversation with Med Supply’s Mike Smith, Clinical Director and Prosthetist

Med Supply’s Clinical Director and Prosthetist, Mike Smith, has a lot to share regarding the process of creating prosthetics, from adjustable post-operative Prosthetics to definitive custom made Prosthetics.

Q: What’s the first step for a patient receiving a prosthetic?

A: “After they have their surgery and their suture line is very fragile, they would be fit with an adjustable post-operative prosthesis a day or two after their surgery. It protects their residual limb. It’s designed of soft, breathable padding. I will go see them in the hospital usually and I will fit this device to them. A few years ago a doctor came to me and said ‘Can you do something that will breathe and let my patients be comfortable and protect their amputation?’ so this is what I came up with. Their residual limb fits into the device. I trim the top so it’s below their knee, I wrap it up to protect their limb, I secure straps above their knee and that’s what holds it on. There’s a reinforcement plate in the back that keeps their knee straight so that they stay protected. I am happy to report it has saved some stumps already! We keep these ready for the post surgical calls that we get.”

Q: Do you have prepared or “off the shelf” prosthetic pieces for your patients?

A: “For prosthetics, everything is custom. There is nothing “off the shelf” that we pull off and deliver as our finished product. There are products that we use off the shelf but the socket part is always custom (the part which the limb stump fits into). The way we currently do it is every patient’s residual limb is hand casted, there are other ways to do it but typically this is how we are doing it.

Once I have a mold of the patient’s residual limb then we put it in the plaster box and fill it with plaster. Once it’s filled with plaster it is stripped and modified so that we can adjust it to measurements and make sure that the weight bearing areas are getting pressure when the patient stands on the prosthesis. The typical process from there is to make what is called a test socket or diagnostic socket. 90% of the time we are doing a weight bearing fitting with that, usually in the parallel bars and seeing how it fits. (Med Supply has a room in-house dedicated to patients testing out prosthesis with parallel bars to walk with support and test stairs to climb.) From that point on we can come back to the mold if we see where it’s not fitting and make adjustments. We may make a second diagnostic socket or we might go right to the final product depending on how good the fit is and based on the patient’s feedback.”

Q: So you have your clients come in to test the diagnostic socket in the practice area of the Med Supply building?

A: “We see patients in our two offices in Troy and Taylor. We also see patients in hospitals, nursing homes and patient’s homes depending on the situation.

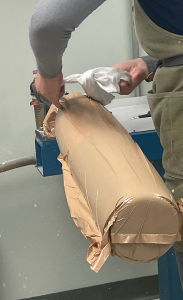

Here is a diagnostic socket that I fit yesterday. The gentleman actually got up and walked ten laps in the parallel bars. It was awesome to see, he did very well so I know this socket is good. Morgan (Mike’s coworker) is going to backfill this socket with plaster to preserve the alignment in the jig and then cut off the socket. Then we’re going to do what is called a lamination. So the final product is a laminated socket made from epoxy resins and different layers of material to create strength. We use a lot of carbon fiber and similar materials that are high strength to weight ratio products. These are very solid. The prosthesis itself is kind of put together like Lego pieces. The parts of the prosthesis, socket, knee (if above the knee amputee), pylon and foot are all connected by mechanical adaptors. The various parts can be disconnect and replaced if needed.”

Q: How long does it typically take for someone to get used to their prosthetic?

A: “Everybody’s different. Usually it’s a process of two to three weeks minimum.”

Q: Do you do any coloring matching for prosthetics?

A: “We do have color swatches that we try to match to the patients skin tone as best as we can. There are skins that go over the prosthetic on the outside so the skin color is as closely matched as possible.”

Q: Do you do custom designs for the socket?

A: “We tell people if you have a shirt or design you want on the outside of your prosthesis, they can provide the material to us and we will put it as the last layer in the process. I’ve done some really cool ones. One lady brought in a Prince, Purple Rain concert shirt and we put that on the prosthesis. We use the shirt in the lamination and it becomes the outside layer, laminated as the final product.”

Q: Are there many options for the full prosthetic?

A: “The majority of amputees wear a liner or interface. A liner is worn on the skin first to prevent irritation, provide cushioning and to provide a connection between limb and prosthesis. There are hundreds of those products available. Then we have prosthetic feet, all of these are based on what the patient is capable of using and what their insurance will pay for. The prosthetic feet range from a very basic design to a very high tech Bionic foot. The high tech feet are carbon fiber, energy storing/returning, there are feet with a vertical shock so on contact it reduces pressure in the socket. There are microprocessor controlled Bionic feet that literally lift the toe as you walk so you don’t catch your toe, very high tech, very expensive.”

Q: Is there a large difference between an above the knee and below the knee prosthetic?

A: “Absolutely. In terms of cost, the cost goes up for above the knee prosthetics. In terms of function, when you have to control two joints, meaning your knee and your ankle, the difficulty goes up. The energy expenditure goes up when you are above the knee, not just doubled more like quadrupled. There are a lot of differences really.”

Med Supply offers an array of options for your prosthetic needs, including:

Below the Knee and Above the Knee Preparatory Prosthesis (Initial or Training Prosthesis)

Below the Knee and Above the Knee Definitive Prosthesis

Microprocessor Controlled Prosthetic Knees

Microprocessor Controlled Prosthetic Feet

If you or someone you love is looking to have a prosthetic made, please contact Med Supply at 866.633.7778. If you have further questions, check out our page on Orthotics and Prosthetics.

Want to see the creation process of a prosthetic? Follow us on TikTok!